On Route

The Big Idea

A multi disciplined design specialist has come up with a radical urban transport proposal, called On-Route, which he believes tackles the two biggest problems caused by city-centre transport today; congestion and pollution. Hugh Frost’s Freight*BUS™ is an innovative new design that combines a passenger-carrying bus with that of freight haulage with the minimum of disruption to either service. It can be reconfigured in seconds by the conductor or driver to carry freight and passengers. Furthermore, passenger space & freight space can be easily adjusted to match demand.

A multi disciplined design specialist has come up with a radical urban transport proposal, called On-Route, which he believes tackles the two biggest problems caused by city-centre transport today; congestion and pollution. Hugh Frost’s Freight*BUS™ is an innovative new design that combines a passenger-carrying bus with that of freight haulage with the minimum of disruption to either service. It can be reconfigured in seconds by the conductor or driver to carry freight and passengers. Furthermore, passenger space & freight space can be easily adjusted to match demand.

Frost’s proposal was submitted to Transport for London (TfL)’s ‘A New Bus for London’ competition, which Mayor of London Boris Johnson launched earlier this year. Although the Freight*BUS was not the final winner of the competition, Hugh Frost, designer and concept originator of the On-Route system and the Freight*BUS still wishes to take his idea to the next level and is now looking for stakeholders to help him do this. These could be in the form of bus or commercial vehicle manufacturers who are interested in developing the Freight*BUS from conceptual state into a full-blown prototype; a municipality which would consider trialling the On-Route system, or stakeholder investors, such as venture capitalists that specialise in environmental transportation solutions.

Low bus occupancy statistics (as low as 15%) prove that buses are a major contributor to pollution, CO² emissions and congestion. Increasing the number of buses will simply add to the problems. A radical approach is needed to make the modern city bus truly efficient, cost effective and sustainable.

“Taking London as an example, the most optimistic proposals put the average occupancy of its buses at 25%. However, our calculations show that for around four hours a day, their utilisation drops to as low as 20%,” Frost says. “Despite this, city authorities are tasked with increasing the numbers of vehicles, routes and service frequency to supposedly reduce congestion and improve services. My idea is to put our cities’ buses to good use by using them to provide an alternative city freight system at times of low passenger capacity utilisation. This could reduce the numbers of freight vehicles on city roads by as much as 30%. By using the buses to carry freight in the evening and overnight, the utilisation of these vehicles would be maximised, offering maximum return on investment (ROI) and substantially increased revenue from the vehicles. However, in order to fulfil this dual role, the entire concept of buses, as we know them today, needs to be re-visualised.”

A real ‘step change’ in city transportation logistics, Freight*Bus marks the integration of passenger and freight transportation. It will have a profound impact on city infrastructure, providing increased passenger and freight capacity, improved convenience and service, whilst reducing congestion, pollution and real costs.

1. Seats in full down position

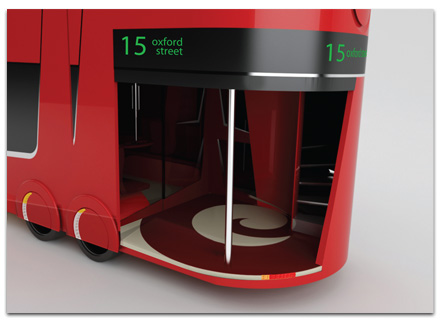

2. Lift parked in up position seals off floor, screen doors closed, preventing access when in passenger mode, will have luggage pod on the frame to provide luggage storage of 1.5m3 accessed by lowering lift to platform, if required for wheel chair access, luggage pod is stored in upper area & lift used independently.

3. Climate control system in this area attached to barn doors, to enable access for freight pods when dock loading from the rear

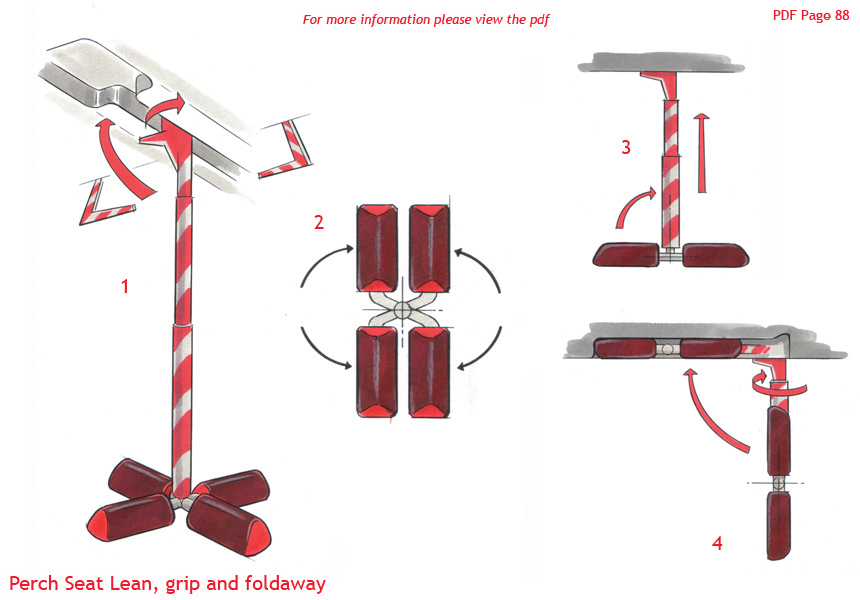

1. Perches deployed for assisted standing in rear compartment.

2. Dividing doors push button open or conductor control open or closed settings for compartment separation (safety use of lift or passengers segregation)

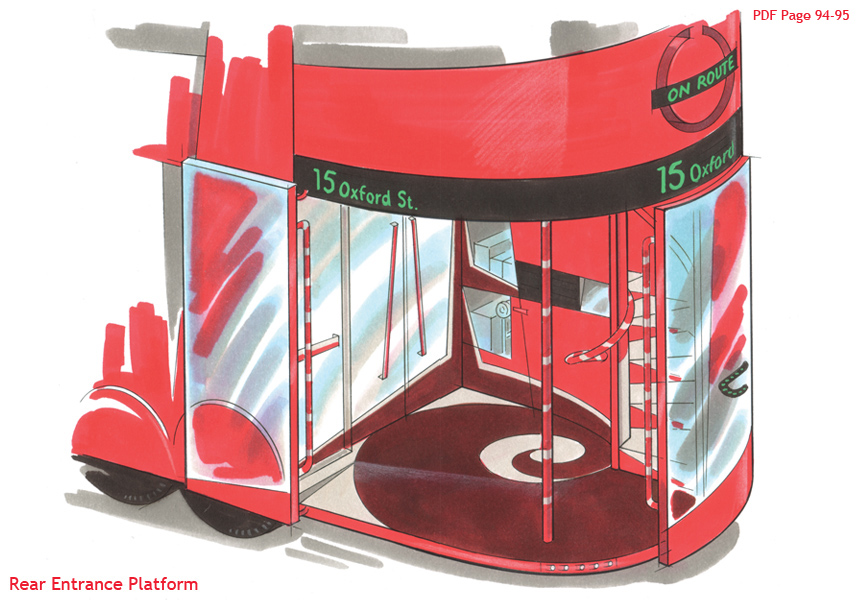

3. Platform segment door (out & slide) to open

4. Platform segment door ( out & slide) to open

5. Front access doors, out & slide

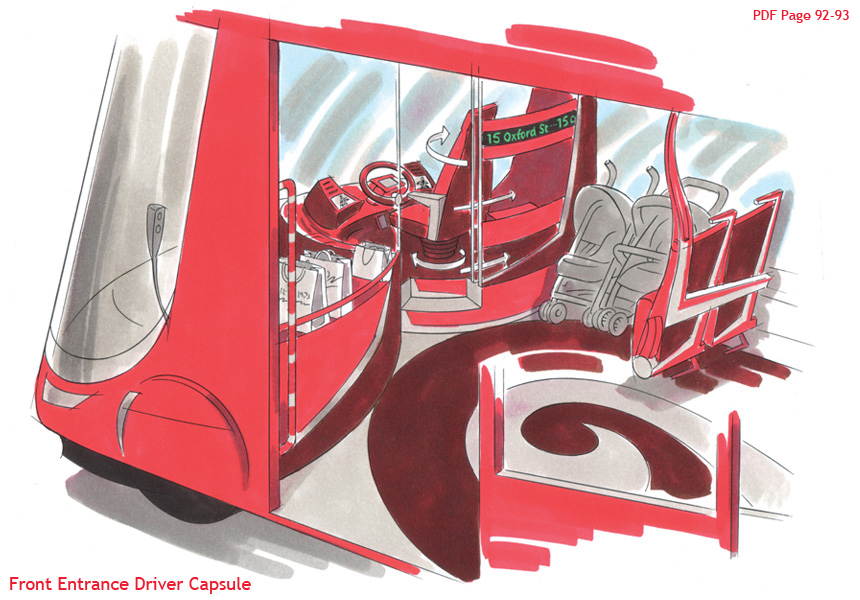

6. Driving capsule separation screen

7. Generator & engine compartment (if required)

The design of Freight*BUS will readily accommodate battery or fuel cell technology. The 200mm deep space in the main floor of the bus will house batteries or fuel cells and the accompanying hydrogen storage tanks (if required). Indeed, it is envisaged that when fuel cell technology is affordable, that the fleet could be easily switched to this propulsion system, while keeping the drive motors and control systems in place. Similarly, its re-configurable interior design could even be broadly applied to existing vehicles built with combustion engines. However, it is the designer’s view that the latest and emerging advances in battery technology will make the re-fit and the use of hydrogen and fuel cells unnecessary. Freight*BUS would also feature the very latest in other emission-saving technology , such as distributed wheel motors which can be as much as 50% more efficient that central motors

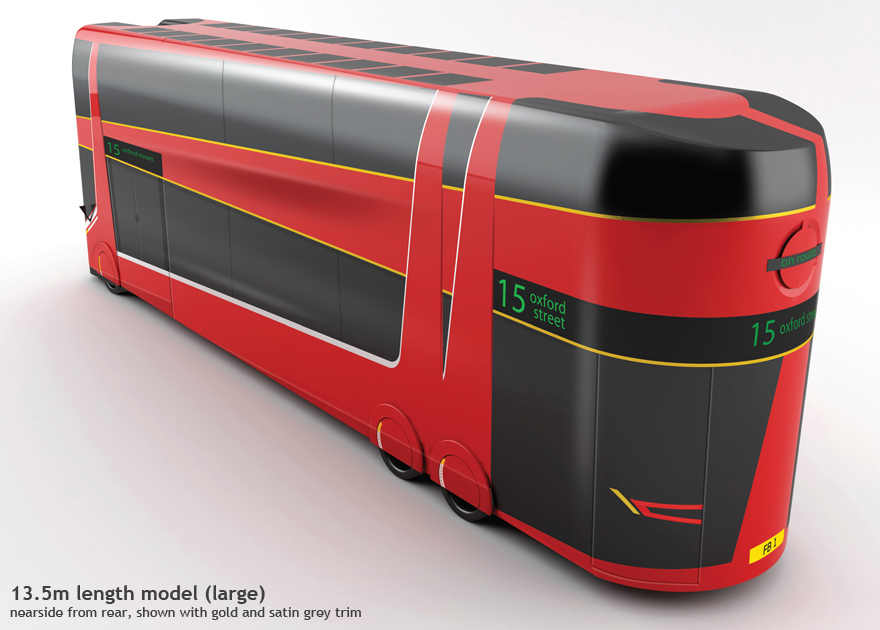

A new city bus ‘On Route’ successfully integrates cutting-edge technology whilst retaining well-loved proven features of the traditional double-decker.

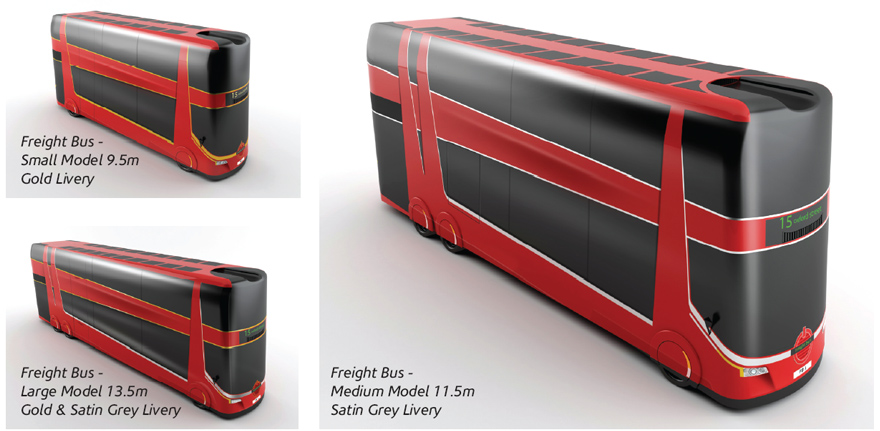

A new iconic design of double-decker bus, ‘freight bus’, is a full car length shorter than the “bendy bus”. In maximum seated mode it will seat a whopping 43 more passengers than the bendy bus. At night time when not carrying passengers it can deliver up to 34 pallets when fully loaded.

How an integrated passenger & freight delivery system meets all major city transportation issues…

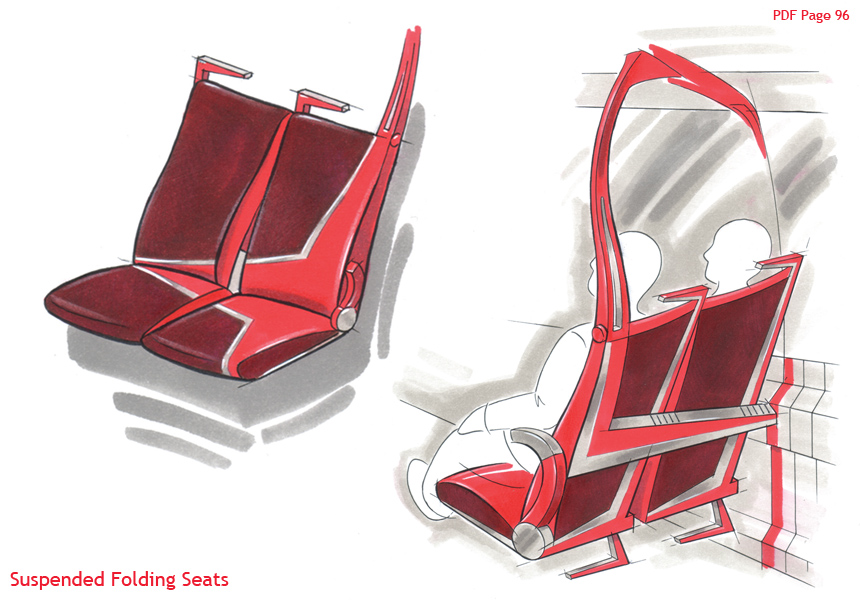

In respect of carriage versatility, seating is suspended from the ceiling and can be configured for almost any combination of passenger & freight space between these limits. This is achieved by designing the seating to be folded away. In fact, each 2 person seat (on both decks) can be folded into the ceiling in seconds.

Seats are fixed to the ceiling through special anti-vibration mounts to improve ride quality. In terms of the vehicle’s freight-carrying capabilities, a pallet-less lifting & handling device is key to easy loading/unloading. Indeed, a crucial part of the interior design is a compact, low cost pod handling system, which has patent protection.

When you take a seat on the ‘On Route’ bus your comfort is assured. The seats are supported by anti vibration mountings and personal efficient ventilation & heating systems for every seat. Freight*Bus rolls into motion without any belching fumes and engine roar. Its all electrical operation allows it not only to accelerate and cruise efficiently, but will emit no pollution or CO² when running on ‘green’ centrally generated electricity.

The interior design is driven by the exterior and is a continuation of the strong functional form resulting in simple geometric shapes as the foundation for all the individual parts, subtly blended to create comfortable, ergonomic forms. The subliminal message is one of sound construction, safety, and functionality, harmonised with the asymmetry of the smooth, highly reflective, streamlined foundation form manifest in the external lines. These forms reinforce the sense of ‘streamlining’ & ‘mechanism’ associated with futuristic transportation.

A unique opportunity to develop a revolutionary new city bus for the 21st century

Freight*Bus marks the convergence of social, economic and environmental issues with automotive technological advances. The time is right to make that quantum leap to change radically the way the humble bus serves the people of the modern city.

How do they do that?

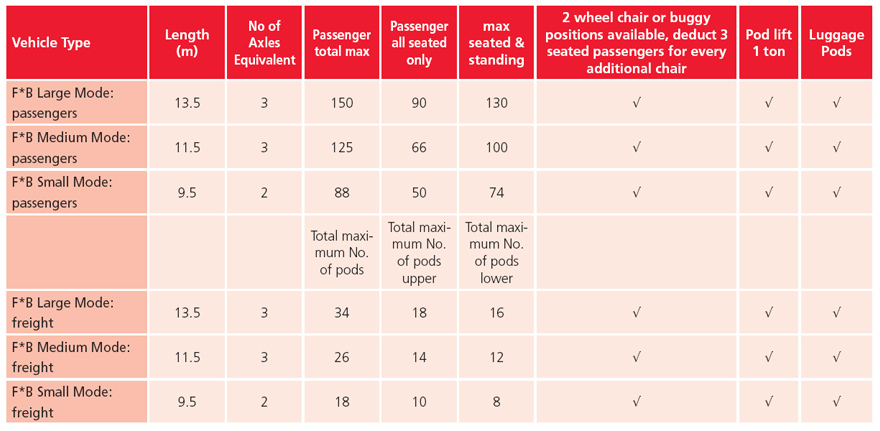

We have designed a range of vehicles based on the same modular construction and technology. This would enable manufacturers to achieve greater ‘economies of scale’ and better ‘Return On Capital Employed’ for manufacturing facilities and tooling investment. Basic vehicle specifications can be seen in the table and are also illustrated below. Refer to the PDF for images.

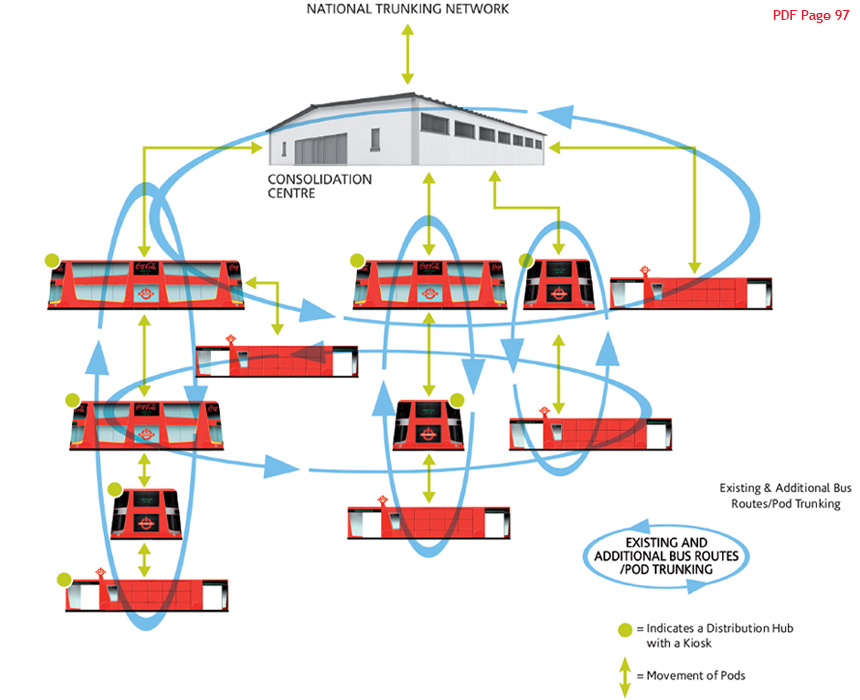

When looking at the idea of consolidation in relation to bus routes and passenger transport, Frost quickly realised that not only were there opportunities to improve bus routing & linking with other transport services and types using consolidation principals, but that there is an even bigger opportunity to use the buses for freight as well as passenger movement that would reduce the numbers of goods vehicles on city roads (especially light goods vans which are responsible for 15% of all UK carbon emissions from all forms of transportation) by as much as 50%. He remarks: “We looked at passenger & freight systems end to end and concluded that there is sufficient overlap to be able to build on and integrate existing infrastructure of both passenger & freight systems. However, it will be necessary to develop consolidation centres and cross-docks for freight movement and hubs for passenger and freight delivery and collection. Many of these elements already exist and can be linked into existing infrastructure such as bus/rail stations & depots; haulage/sorting depots etc. Hubs would also be located at major bus stops, and concentrations of retail, commercial & light industrial units.

Frost points to studies which have already been carried out in London showing that the implementation of alternative freight systems, including the use of ‘Consolidation Centres’ in city areas can give exceptional results. One such study found a 68% reduction in construction vehicles entering the City of London for the project, an average journey time reduction of 2 hours, a circa 75% reduction of CO2 emissions, and a 10% reduction in local distribution journey times. The On-Route Bus supports the existing aims of the London Freight Plan as set out of in the Mayor of London’s existing Transport Strategy.

The new ‘On Route’ concept bus, (9.5m length - small model) is only two cars in length. It can carry 90 passengers when fully loaded - that’s half the length and 20% less road space per passenger than the Bendy-Bus. All that, without the road blocking and manoeuvring issues of the juggernaut bendy.

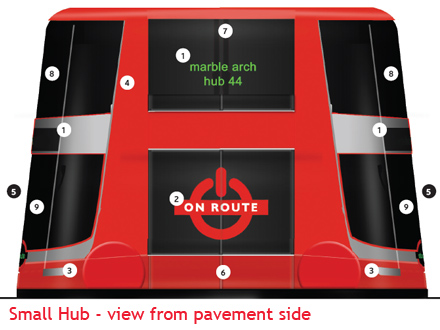

1. Hub ID Ref and realtime data

2. Illuminated logo and access doors

3. Headlights to become pavement downlights

4. Structural member as in Freight*Bus

5. Open view to oncoming traffic/buses

6. Double opening doors - Oyster card controlled if required, controlled access

7. Possible digital advertising space.

8. Upper level Pod storage

9. Clear windows

1. Hub ID Ref and realtime data

2. Illuminated logo and access doors

3. Headlights to become pavement downlights

4. Structural member as in Freight*Bus

5. Open view to oncoming traffic/buses

6. Double opening doors - Oyster card controlled if required, controlled access

7. Possible digital advertising space.

8. Upper level Pod storage

9. Clear windows

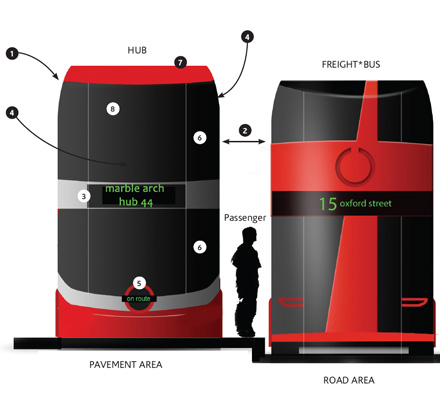

1. All components pre-fabricated using Freight*Bus body parts adapted for construction and pre-assembled. “Drop-off Plug-in & Play” fully insulated and building regulations compliant.

2. Separation gap can be from 0.5m to 3m.

3. Signage information display.

4. Possible digital advertising space.

5. Corporate Identity.

6. Upper area Pod storage serviced by Pod Lift inside Hub. Lower area Lift and Kiosk space with Bus Shelter providing security, heat and light for passengers.

7. Roof to have photovoltaic cells to provide green energy.

8. Upper areas to be insulated panels not glazed (appearance of glass panels).

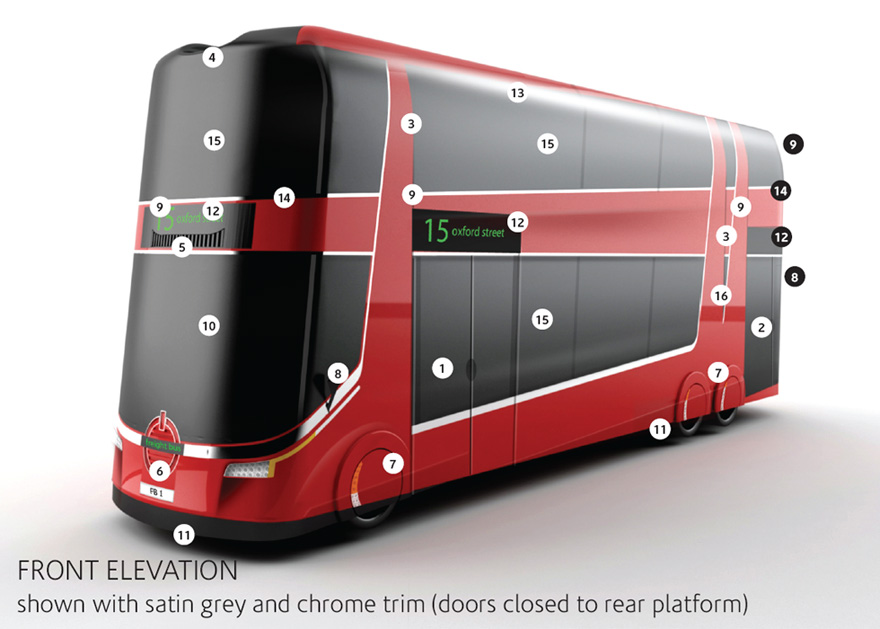

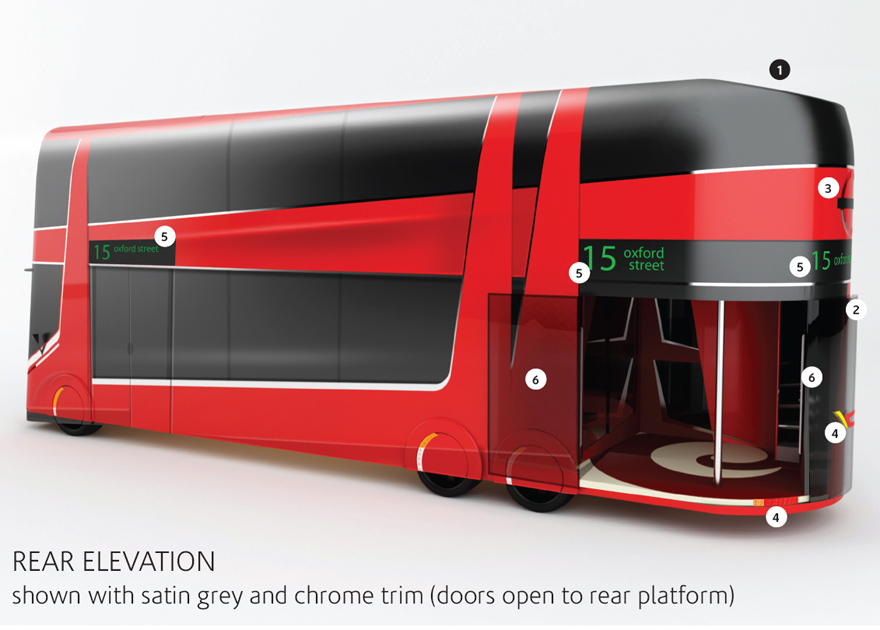

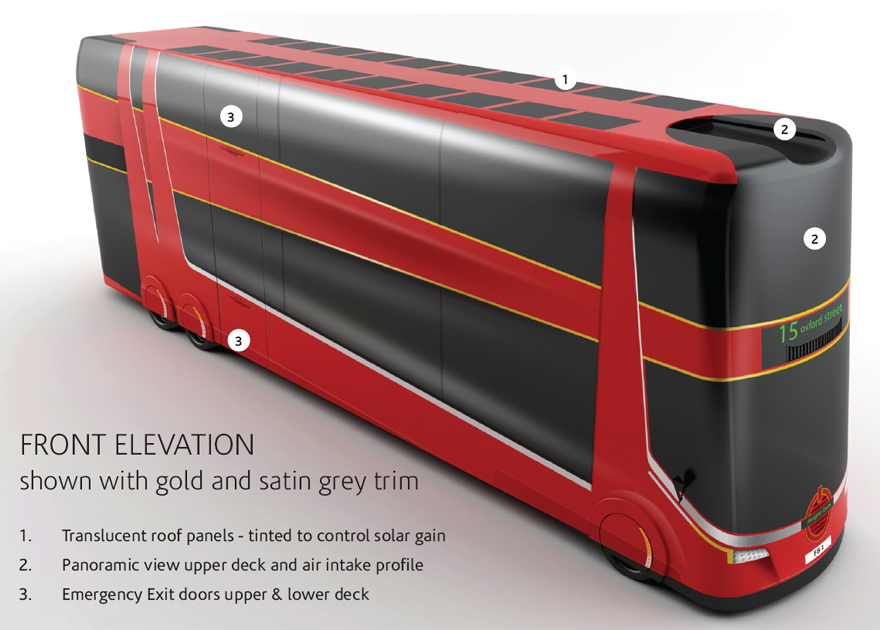

1. Near side passenger front access - pair of sliding doors

2. Rear open platform or pair of sliding doors

3. Structural members emphasised as a design feature

4. Contoured roof detail to direct air intake flow for environment control system and panoramic sky views

5. Air intake for environment control system

6. Air intake for engine cooling (if applicable). Also for driver air-con system. Styled to provide unique distinctive character.

7. Hub and wheel covers with sliding panel system to allow for suspension movement and wheel turning. All incorporate indicators, sidelights.

8. Wing mirror camera and reversing camera - rubber/spring mounted and discreet - improved driver visibility

9. External CCTV surveillance camera(s)

10. Large clear view windscreen

11. Underslung deflector skirt for fallen pedestrian/cyclist safety

12. High visibility information display

13. Curved roof corner detail to reduce cross wind effect

14. Contoured smooth lines to improve aerodynamics

15. Large, smooth visible window panels (no visible or protruding seals) - no opening windows

1. Drop roof profile over storage area to improve aerodynamics and enhance style

2. Semi-circular rear profile to reduce air turbulence drag, accentuate the iconic platform and spiral staircase design

3. Ventilation/Environment controlled exhaust, stylised to corporate identity

4. Rear lighting LED’s and indicators exposed when platform doors open

5. High visibility information display

6. Optional opening doors or open platform

The new ‘On Route’ bus has all the easy access feature of a modern bendy: wide access doors, low floor, high capacity, but with the enormous benefits of 50% less road space. Freight*Bus’ great manoeuvrability is helped by a unique front & rear steering system that even enables the bus to move sideways into bus stops - ‘perfect parking’. And when the bendy- bus goes to bed at night taking up space for two double-decker buses, the new bus carries on working, transforming itself into a giant silent delivery vehicle. ‘Freight*bus’ - no noise, no pollution, all electric.

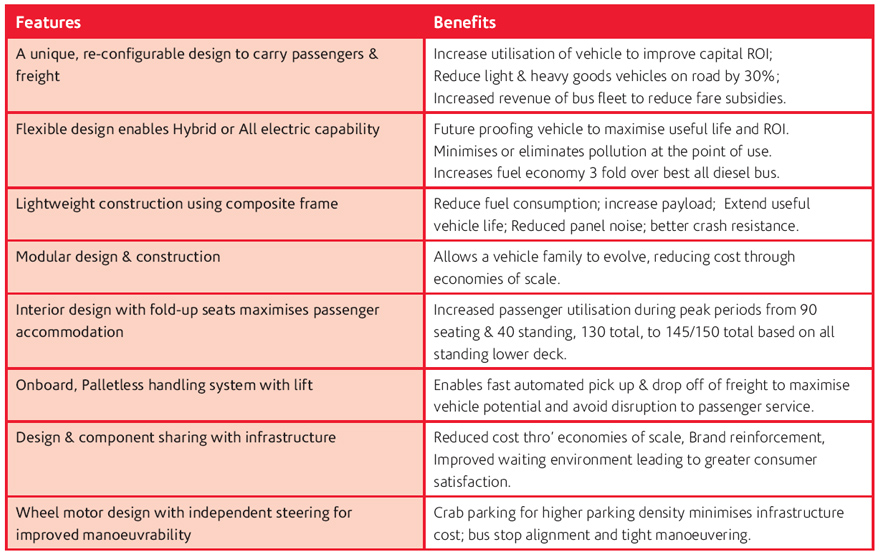

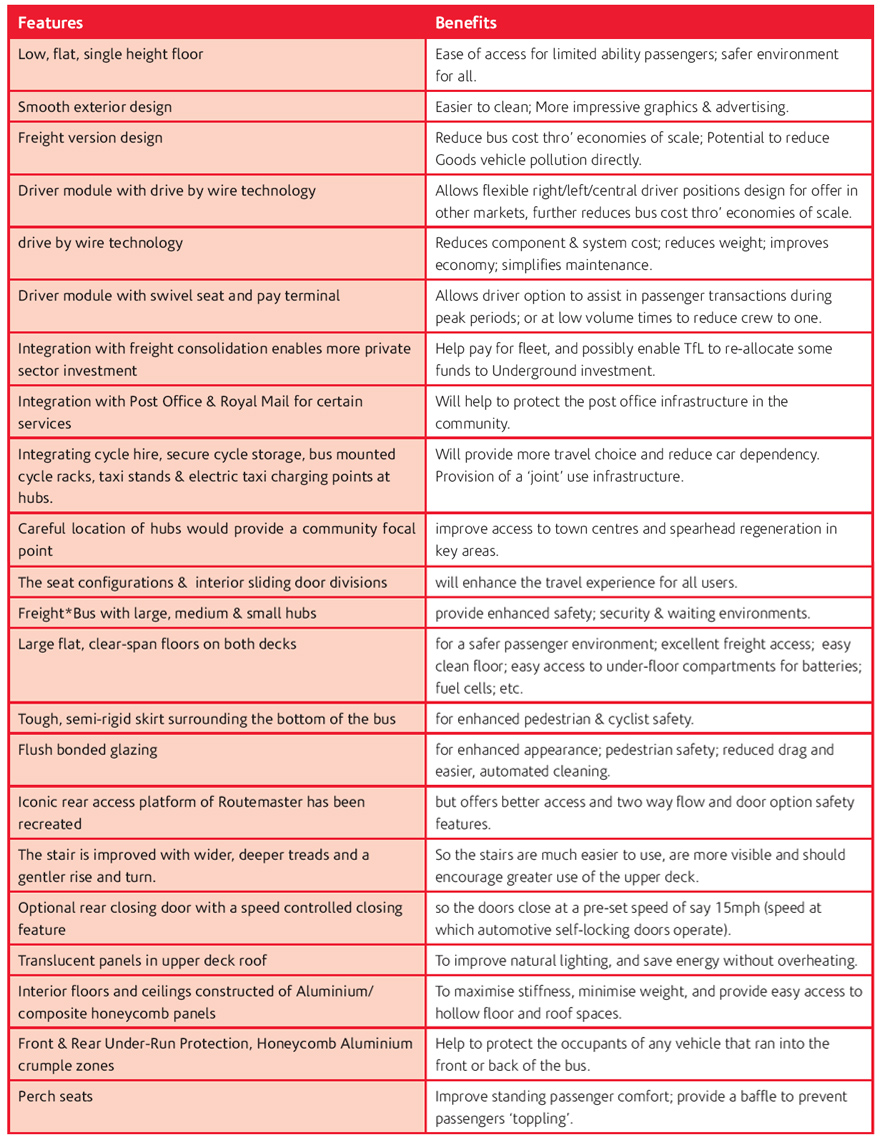

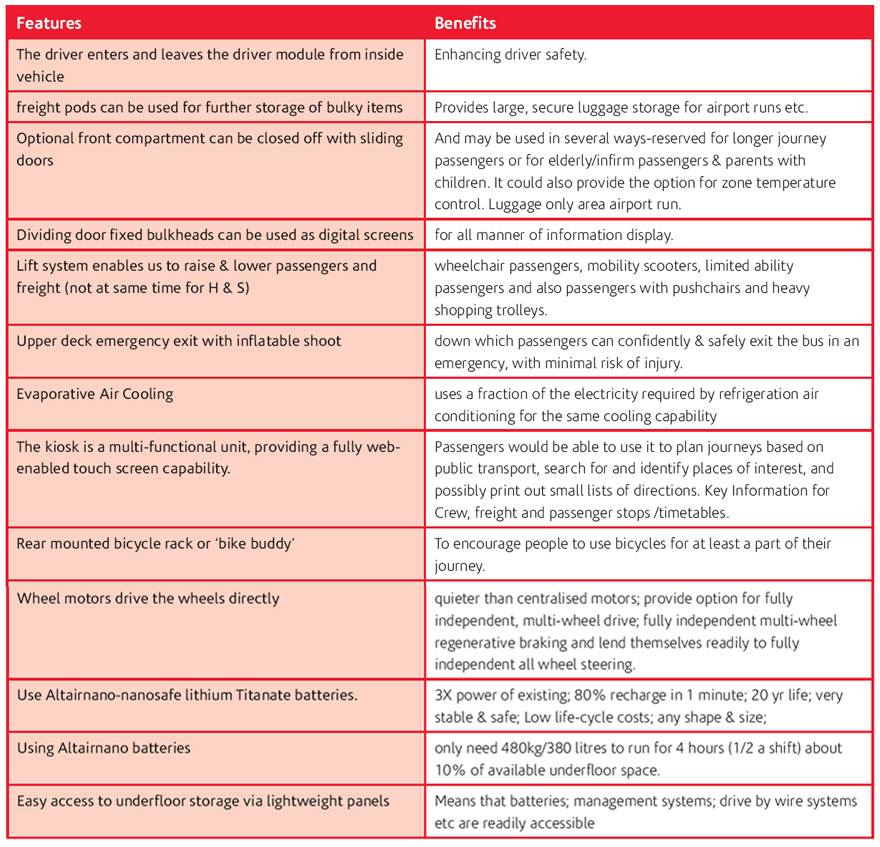

The Features and Benefits of the Freight*Bus

We believe our ‘big idea’ would revolutionise city freight handling and profoundly change the economics of passenger transport for the better, while making significant reductions in congestion and pollution.

Sharing of capital costs, operational costs and revenues across passenger and freight sectors could enable both sectors to flourish, where at present passenger transport is heavily subsidised, and where the commercial freight sectors struggle to make money and are reluctant to deliver within London.

Our idea would achieve or positively influence ALL ten key transport priorities that the previous Mayor of London had identified, and will achieve or positively influence ALL seven of the main objectives of the London Freight Plan. These are:

- Support London’s growth in population and economic activity

- Improve the efficiency of freight distribution and servicing in London

- Balance the needs of freight and servicing with those of other transport users and demands for London’s resources

- Tackle poor air quality & climate change by reducing emissions of air pollutants and CO2

- Improve quality of life in London by minimising the impact of noise and vibration caused by freight and servicing

- Improve health & safety by reducing the number of deaths and injuries associated with freight movement and servicing

- Improve quality of life in London by reducing the negative impacts of freight and servicing on communities

Table summarising the Features & Benefits of Freight*Bus and an integrated Passenger & Freight System

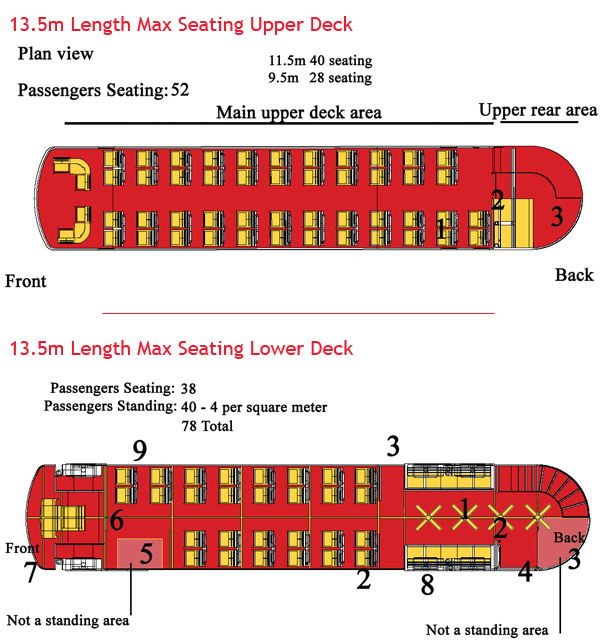

The 13.5m version boasts when fully loaded seating for 52 and standing for 90 passengers, compared to the bendy maximum capacity of 47 seats and 111 standing.

Overcoming so many of the problems of the bendy bus, Freight*Bus demonstrates a unique manoeuvrability made possible by the revolutionary all wheels steering. The new double-decker also has all the easy access features, low floor, high capacity quick entry and alignment.

Alternate Vehicle Configurations

We have designed a range of vehicles based on the same modular construction and technology. This would enable manufacturers to achieve greater ‘economies of scale’ and better ‘Return On Capital Employed’ for manufacturing facilities and tooling investment. Basic vehicle specifications can be seen in the table and are also illustrated below. Refer to Drawings ref 12.3 - Plans of Upper and Lower Deck for all versions.